The pellet skimmer retaining plastics

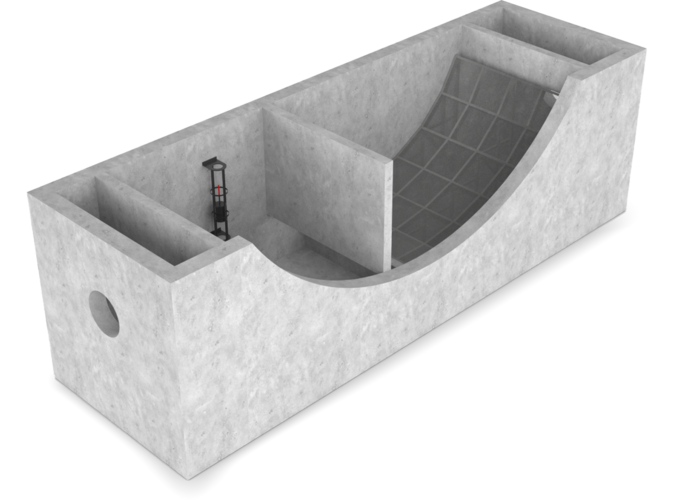

Granulo Smart

--------------------------------

- Retains plastics down to 50 microns

- An easy and efficient separation technique

- Minimal maintenance thanks to self-cleaning filters

A unique "plastic soup" separator

This innovative separator that retains plastic granulates down to no smaller than 50 microns, helps combat plastic pollution. The unique water flow technique ensures the separation and storage of the pellets.

These separators are used at transshipment companies and by industries processing plastic pellets. The separators have been installed at various locations across the world including in Belgium (e.g. the Port of Antwerp).

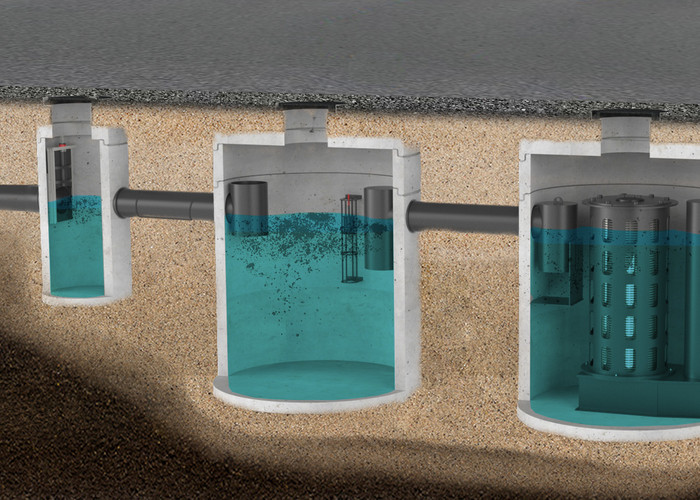

How does the microplastics separator work?

Counters plastic pellets losses

Pellets is plastic in granular form that serves as a raw material for a variety of plastic end products. The Granulo Smart pellet separator was designed especially for producers and processors of plastic granules and transshipment companies.

The plastic granules are usually transferred into big-bags, bulk goods vehicles or silos. During loading and unloading pellets are spilled on the transshipment site. These spilled pellets then enter our environment in the rainwater drainsystem.

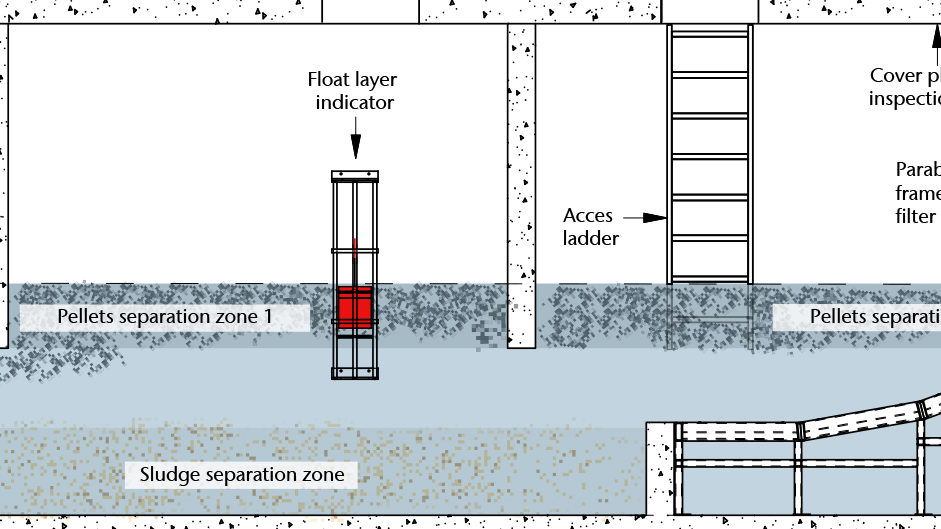

The optimal separation technique

With the even distribution of water flow and specific water velocities in each zone, one obtains an optimal separation effect. Slowing causes settling and separation. Special techniques are deployed to retain settling particles and create a lift effect to enhance flotation. A retaining wall is also used to hold back the floating layer.

Accelerating and densifying the water flow creates an upward flow in which (semi-) suspended particles are catapulted into the floating layer. Then cohesion causes them to adhere to the separated larger light particles. The hydraulic design ensures that soiling is separated and retained. The filter is then loaded as little as possible.